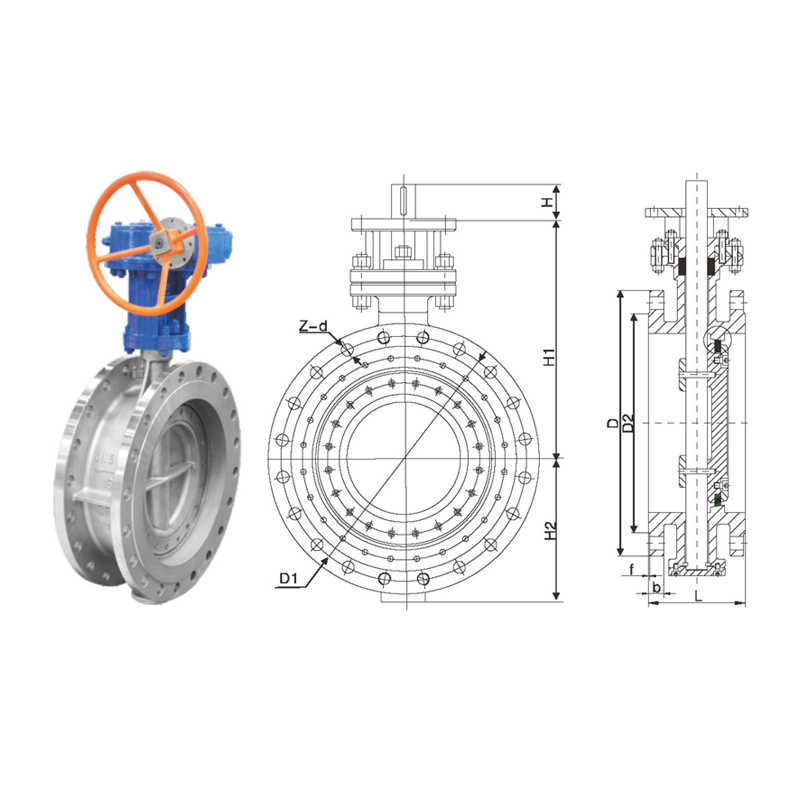

Flanged triple eccentric butterfly valve

Key words:

Classification:

Product Description

Application specification Application Of Norms

Design standards: API609, JB8527, DIN2559, EN593

Application specification

1. Pressure range: CLASS 150Lb-1500Lb PN6-PN150

2. Nominal diameter: NPS 2-80 ° DN50-2000mm

3. Main body material: carbon steel, stainless steel, duplex stainless steel, alloy steel, nickel alloy steel

4. Connection form: flange type

5. Working temperature: -29 ℃ ~ 350 ℃

6. Operation mode: handle, worm gear, electric device, pneumatic device, hydraulic device, gas-liquid linkage device

Material Material for main parts

|

Serial Number NO |

Part Name Parts name |

Materials Material |

Serial Number NO |

Part Name Parts name |

Material |

|

1 |

End cap End cap |

ASTM A105 |

|

Sealing ring Seal ring |

ASTM A276304 Graphite |

|

2 |

Hexagon Socket Screw Inner six angle screw |

ASTM A193 B7 |

|

Hexagon Socket Screw Inner six angle screw |

ASTM A193 B7 |

|

3 |

Gasket Gasket |

flexible graphite 304 Eeybla araphi |

|

Pressure ring Pressure ring |

ASTM A105 |

|

4 |

Lower shaft sleeve ower bushing |

304 |

9 |

Pin Pin |

ASTM A193 B7 |

|

5 |

Valve body Body |

ASTM A216 WCB |

10 |

Right sealing ring Right sealing ring |

flexible graphite Flexible graphite |

|

6 |

Pressure ring Retaining Ring |

ASTM A105 |

11 |

Upper shaft sleeve Upper shaft sleeve |

304 |

|

7 |

Hexagon Socket Screw Nner six angle screw |

ASTM A193 B7 |

12 |

Stem Stem |

17-4PH |

|

8 |

Butterfly plate assembly Diso assembly |

Component drawing Component diagram |

13 |

Packing gland Gland |

ASTM A216 WCB |

|

|

Butterfly plate Disa |

ASTM A216 WCB |

14 |

Bracket Bracket |

ASTM A216 WCB |

|

|

Adjusting pad Adjusting pad |

flexible graphite Flexible graphite |

15 |

Cited Rise Double Bowl |

ASTM A193 B7 |

Note: Caliber ≤ 24 'according to ANSIB16.5 Caliber> 24' according to ANSIB16.47 Series B

Notes:Size≤24" according to ANSIB16.5,Size>24" according to ANSIB16.47Series B

Appearance and connect dimensions

Unit: mm

| Nominal diameter Nominal diameter |

L |

D |

D1 |

D2 |

b |

f |

Z-d |

M |

H |

H1 |

H2 |

|

1.6MPa |

|||||||||||

|

50 |

108 |

165 |

125 |

102 |

20 |

3 |

4-18 |

M16 |

50 |

200 |

75 |

|

80 |

114 |

200 |

160 |

138 |

20 |

3 |

8-18 |

M16 |

50 |

226 |

98 |

|

100 |

127 |

220 |

180 |

158 |

22 |

3 |

8-18 |

M16 |

50 |

250 |

130 |

|

125 |

140 |

250 |

210 |

188 |

22 |

3 |

8-18 |

M16 |

55 |

295 |

165 |

|

150 |

140 |

285 |

240 |

212 |

24 |

3 |

8-22 |

M20 |

60 |

315 |

175 |

|

200 |

152 |

340 |

295 |

268 |

24 |

3 |

12-22 |

M20 |

65 |

380 |

220 |

|

250 |

165 |

405 |

355 |

320 |

26 |

3 |

12-26 |

M24 |

65 |

405 |

250 |

|

300 |

178 |

460 |

410 |

378 |

28 |

4 |

12-26 |

M24 |

70 |

480 |

300 |

|

350 |

190 |

520 |

470 |

428 |

30 |

4 |

16-26 |

M24 |

70 |

545 |

330 |

|

400 |

216 |

580 |

525 |

490 |

32 |

4 |

16-30 |

M27 |

100 |

550 |

360 |

|

450 |

222 |

640 |

585 |

550 |

40 |

4 |

20-30 |

M27 |

100 |

620 |

380 |

|

500 |

229 |

715 |

650 |

610 |

44 |

4 |

20-33 |

M30 |

105 |

680 |

410 |

|

600 |

267 |

840 |

770 |

725 |

54 |

5 |

20-36 |

M33 |

105 |

750 |

460 |

|

700 |

292 |

910 |

840 |

795 |

40 |

5 |

24-36 |

M33 |

110 |

820 |

530 |

|

800 |

318 |

1025 |

950 |

900 |

42 |

5 |

24-39 |

M36 |

130 |

910 |

610 |

|

900 |

330 |

1125 |

1050 |

1000 |

44 |

5 |

28-39 |

M36 |

140 |

930 |

640 |

|

1000 |

410 |

1255 |

1170 |

1115 |

46 |

5 |

28-42 |

M39 |

140 |

980 |

720 |

|

1200 |

470 |

1485 |

1390 |

1330 |

52 |

5 |

32-48 |

M45 |

170 |

1220 |

820 |

|

1400 |

530 |

1685 |

1590 |

1530 |

58 |

5 |

36-48 |

M45 |

180 |

1310 |

930 |

|

1600 |

600 |

1930 |

1820 |

1750 |

64 |

5 |

40-55 |

M52 |

190 |

1460 |

980 |

|

1800 |

670 |

2130 |

2020 |

1950 |

68 |

5 |

44-55 |

M52 |

200 |

1560 |

1090 |

|

2000 |

760 |

2345 |

2230 |

2150 |

70 |

5 |

48-60 |

M56 |

200 |

1670 |

1190 |

Appearance and connect dimensions

Unit: mm

| Nominal diameter Nominal diameter |

L |

D |

D1 |

D2 |

b |

f |

Z-d |

M |

H |

H1 |

H2 |

|

2.5MPa |

|||||||||||

|

50 |

108 |

165 |

125 |

102 |

20 |

3 |

4-18 |

M16 |

50 |

200 |

75 |

|

80 |

114 |

200 |

160 |

138 |

24 |

3 |

8-18 |

M16 |

50 |

226 |

98 |

|

100 |

127 |

235 |

190 |

162 |

24 |

3 |

8-22 |

M20 |

50 |

250 |

130 |

|

125 |

140 |

270 |

220 |

188 |

26 |

3 |

8-26 |

M24 |

55 |

295 |

165 |

|

150 |

140 |

300 |

250 |

218 |

28 |

3 |

8-26 |

M24 |

60 |

315 |

175 |

|

200 |

152 |

360 |

310 |

278 |

30 |

3 |

12-26 |

M24 |

65 |

380 |

220 |

|

250 |

165 |

425 |

370 |

335 |

32 |

3 |

12-30 |

M27 |

65 |

405 |

250 |

|

300 |

178 |

485 |

430 |

395 |

34 |

4 |

16-30 |

M27 |

70 |

480 |

300 |

|

350 |

190 |

555 |

490 |

450 |

38 |

4 |

16-33 |

M30 |

70 |

545 |

330 |

|

400 |

216 |

620 |

550 |

505 |

40 |

4 |

16-36 |

M33 |

100 |

550 |

360 |

|

450 |

222 |

670 |

600 |

555 |

46 |

4 |

20-36 |

M33 |

100 |

620 |

380 |

|

500 |

229 |

730 |

660 |

615 |

48 |

4 |

20-36 |

M33 |

105 |

680 |

410 |

|

600 |

267 |

845 |

770 |

720 |

58 |

5 |

20-39 |

M36 |

105 |

750 |

460 |

|

700 |

292 |

960 |

875 |

820 |

50 |

5 |

24-42 |

M39 |

110 |

820 |

530 |

|

800 |

318 |

1085 |

990 |

930 |

54 |

5 |

24-48 |

M45 |

130 |

910 |

610 |

|

900 |

330 |

1185 |

1090 |

1030 |

58 |

5 |

28-48 |

M45 |

140 |

930 |

640 |

|

1000 |

410 |

1320 |

1210 |

1140 |

62 |

5 |

28-55 |

M52 |

140 |

980 |

720 |

|

1200 |

470 |

1530 |

1420 |

1350 |

70 |

5 |

32-55 |

M52 |

170 |

1220 |

820 |

|

1400 |

530 |

1755 |

1640 |

1560 |

76 |

5 |

36-60 |

M56 |

180 |

1310 |

930 |

|

1600 |

600 |

1975 |

1860 |

1780 |

84 |

5 |

40-60 |

M56 |

190 |

1460 |

980 |

|

1800 |

670 |

2195 |

2070 |

1985 |

90 |

5 |

44-68 |

M64 |

200 |

1560 |

1090 |

|

2000 |

760 |

2425 |

2300 |

2210 |

96 |

5 |

48-68 |

M64 |

200 |

1670 |

1190 |

Related Products

Product inquiry

Guangdong Xiang Anxing Valve Technology Co., Ltd.

Address: No.14, Steel World Avenue, Zone B, Lecang Steel World Stainless Steel, Shunde District, Foshan City, Guangdong Province

Telephone:18024107317

Mailbox:1024706719@qq.com

Website:www.xianganxing.com

Public

Mobile phone official website

Copyright©2023 Guangdong Xiang Anxing Valve Technology Co., Ltd.